Quality Assurance

We are proud to provide the top quality ship launching airbags, together with expert service and timely customer support. Let’s help you successfully complete your project – on budget and on time.

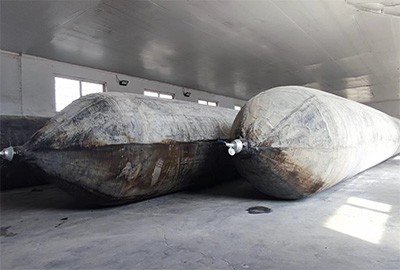

Ship launching airbags are known as roller bags, launching air balloons, inflatable marine airbags, air lift bags, and salvage bags. Ship launching airbags are specialized marine rubber air bags that are used for launching marine vessels. ship landing or haul-outs. Marine rubber airbags are also widely used in loading, floating, lifting and moving sunken ships, and salvaging stranded boats. Rubber airbags are made of heavy-duty synthetic-tire-cord layers with inner and out rubber layers in a long cylindrical balloon shape.

Ship launching or upgrading using marine airbags is an innovative ship launching technology. It overcomes the disadvantage of “end-on launching”, “side ship launching”, “float-out”. This ship launching technology overcomes the restrictions of the fixed launching track of side-launch.

This flexible ship launching technology is accepted by more shipyards worldwide because of its advantages of saving time, saving investment, flexibility, safety. We are constantly innovating in terms of design, material usage, & manufacturing technologies throughout the years to ensure flexibility, safety, and reliability.

Up to now, more cargo vessels, barges, chemical tankers, tugboats, AHTS vessels, floating docks, and even construction caissons have all been launched using our ship launching rubber airbags. The biggest vessel launched by ship launching airbags up to 100,000DWT.

All Doowin Marine ship launching airbags are manufactured and tested fully compliant with ISO 14409:2011 Ships and marine technology — Ship launching airbags. To learn more about technology, please kindly refer to ISO 17682:2013 Ships and marine technology — Methodology for ship launching utilizing airbags

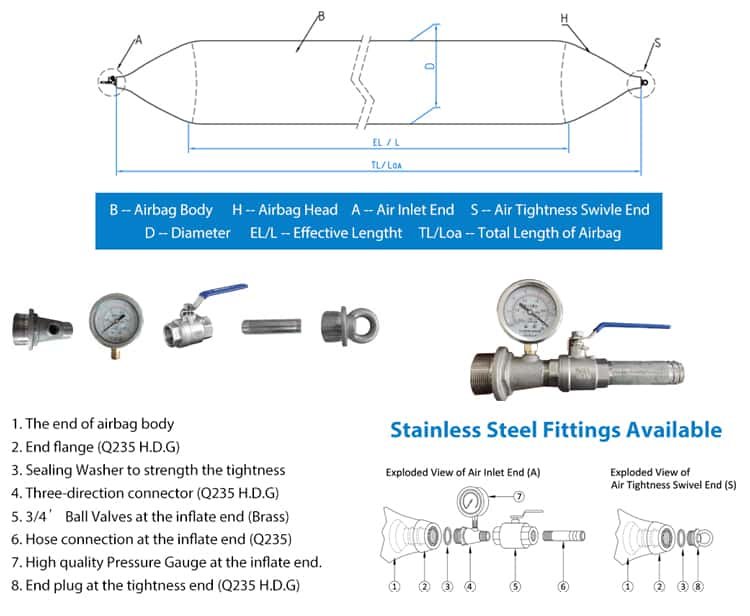

Rubber airbags are constructed of an out rubber layer, multi-layer synthetic-tire-cord layers, and inner rubber layer vulcanized firmly. Rubber airbags are cylindrical balloon body, with two conical head and end mouth. Swivels and air inlet kits are screwed with end mouth.

Synthetic-tire-cord layer is reinforcement layer of the ship launching airbags which are made of rubber coated synthetic-tire-cord fabrics. Many synthetic-tire cord layers are twined at ideal angles by unique and patented "Holistic Wrapping Technology". To hold the internal pressure and to distribute the stress evenly. We use the 1870 dtex/2 type synthetic-tire-cord fabric. The warp is over 95 cords per 100 mm in width. The breaking strength is more than 310 N per cords.

Prior to the air bag production, the outer and inner rubber layers shall be tested to meet the criteria in accordance with the test methods given in the International Standards listed below. The outer rubber layer covers the outside of ship launching airbags. To protects the cord layers from abrasion and other external forces. This compound has sufficient tensile and tear strength to withstand any weather condition and hard usage.

Type No. | Diameter (m) | Initial Internal Pressure for Test (kPa) | Rated Working Pressure (kPa) | Bearing Capacity at 70% compress deformation (KN/m) | Minimum Burst Pressure (kPa) |

|---|---|---|---|---|---|

QP5 | 0.8 | 48 | 210 | 184 | 630 |

1.0 | 35 | 170 | 186 | 510 | |

1.2 | 28 | 140 | 185 | 420 | |

1.5 | 20 | 110 | 181 | 330 | |

1.8 | 16 | 90 | 178 | 270 | |

2.0 | 14 | 80 | 176 | 240 | |

QG6 | 0.8 | 56 | 245 | 215 | 740 |

1.0 | 45 | 200 | 219 | 600 | |

1.2 | 32 | 165 | 217 | 490 | |

1.5 | 25 | 130 | 218 | 390 | |

1.8 | 20 | 110 | 220 | 330 | |

2.0 | 18 | 100 | 220 | 300 | |

QG7 | 0.8 | 64 | 270 | 237 | 810 |

1.0 | 50 | 220 | 242 | 660 | |

1.2 | 38 | 190 | 251 | 570 | |

1.5 | 29 | 150 | 247 | 450 | |

1.8 | 25 | 130 | 257 | 390 | |

2.0 | 23 | 120 | 264 | 360 | |

QG8 | 0.8 | 70 | 300 | 264 | 900 |

1.0 | 54 | 240 | 264 | 720 | |

1.2 | 45 | 210 | 277 | 630 | |

1.5 | 32 | 170 | 280 | 510 | |

1.8 | 29 | 150 | 297 | 450 | |

2.0 | 26 | 140 | 308 | 420 |

Ship Launching air bags are categorized by the following three types according to the bearing capacity, per meter in length. We define the number of layers, which means the number of Synthetic-tyre-cord layers, in order to confirm the Safety Working Pressure. Another type is available upon clients’ request.

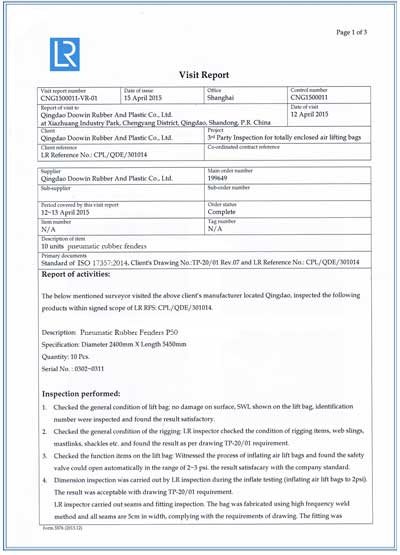

From the raw materials to the highly skilled production process, our engineering team constantly improves. Our rubber rollers are manufactured and tested to comply with ISO 14409, certificated by CCS, LR, DNV. Superior Manufacturing & Quality Control Processes from the selection of raw materials to the highly skilled production process

All our rubber airbags are manufactured and tested comply with ISO 4409 latest edition.

Air bags create high lifting capacity with safer low pressure. One air bag can lift 300~500 ton.

Heavy-duty synthetic-tire-cord layers are the framework material. It can bear high working pressure.

Donot be misled by low price, weak cords with lower number of true layers and more.

Rubber airbags have 6~12 plies reinforcement layers to withstand most abrasion and puncture.

The design lifespan of ship launching rubber airbags is over 6 years with the correct storage.

High-pressure heavy lifting airbags are the toughest large pneumatic lifting bags for the huge structure, concrete caissons lifting and moving. High-pressure heavy lifting airbags is updated based on the ship launching airbags. The highest lifting capacity of each heavy lifting airbag can reach more than 1,000 ton.

Marine rubber airbags are particularly suited for installation buoyancy on pipeline float-out, beach pulls, and river crossings. Our marine rubber airbags have also been used in applications such as vessel and platform draught reduction. Ship launching marine rubber airbags also can be used to salvage the shipwreck, rescue or float the floating bridge.

Doowin Marine is professional MANUFACTURER of ship launching airbags, pneumatic rubber fenders, foam filled fenders, inflatable pipe plugs, and offshore foam buoys.

Doowin Marine is the leading manufacturer of ISO14409:2011 or CB/T 3795 rubber airbags/marine inflatable airbags. Marine rubber airbags, known as ship launching airbags or ship launching balloons can be used for ship launching and landing, heavy lifting, and marine salvage.

Our engineers and consultants have been in fabrication and use these products for more than 30 years. Doowin Marine products passed rigorous ISO 9001:2008 Quality Management System, approved by the third party SGS, BV, CCS, ABS, LR, BV.

We are proud to provide the highest quality products, together with expert service and timely customer support. Let’s help you successfully complete your project – on budget and on time.

It is a non-profit social organization voluntarily formed by enterprises and institutions with professional qualifications such as diving, salvage, rescue, underwater construction, marine engineering services, and related medical security, equipment manufacturing, scientific research, teaching and training institutions across the country.

Tell us your request now, you will get a special 10% OFF for your first order.