Offshore Foam Buoys

Professional Offshore Solid Buoyancy Modules Solution from the surface to subsea 7000msw.

We provide comprehensive range of resilient foam buoys products with advance solid buoyancy material production and polymer engineering. Our offshore buoyancy buoys generally consist of a closed-cell foam core encapsulated with tough, resistant polyurethane outer skin, combined with high quality steel work. We can make subsurface mooring buoys, cable floats, pipeline floaters, ROV buoyancy module, special shape buoys, and other syntactic foam products. The out skin can be made by polyethylene shell and polyurethane elastomer.

Offshore foam buoys are specialized floating devices primarily used in marine environments. Made of lightweight foam material, they exhibit excellent buoyancy and stability, enabling them to maintain a floating state under various sea conditions. These buoys are primarily employed for marking specific areas, warning of hazards, and providing navigation guidance for vessels and maritime activities. Their simple and practical design allows for easy installation and maintenance, while also offering customization options to meet diverse usage requirements. Additionally, offshore foam buoys are environmentally friendly and pose no threat to the marine ecosystem. Their long-term use at sea complements marine environmental protection and rescue operations. Overall, offshore foam buoys are efficient, reliable, and practical maritime equipment widely used in ocean engineering, fishing, diving, and other related marine activities, providing crucial support for maritime safety and navigation.

Application

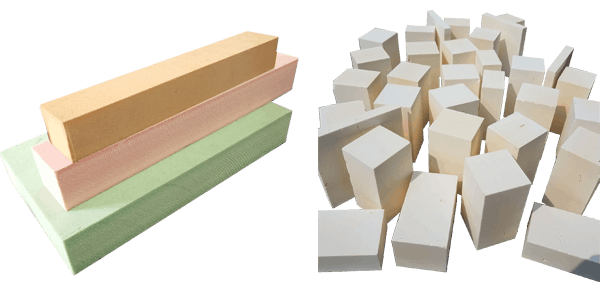

Offshore Surface Foam Buoys

Genereal surface chain support foam buoys and offshore mooring buoys

Our sold buoyancy material is important counterweight material for underwater operation equipment. Our subsea buoyancy material products are used for oceanographic, offshore oil and gas, survey, ROV & AUV. We have various buoyancy materials used for subsea up to 7000m.

LOW DENSITY

The density (0.08~0.7g/cm3) is much lower than the density of water. It povides the greatest possible buoyancy per unit volume.

HIGH STRENGTH

The compressive strength is 1~100Mpa. The pressure resistance is excellent. It can withstand the full range of hydrostatic pressure.

LOW WATER ABSORPTION

Water absorption rate is not more than 3%. It provides stable buoyancy under large waer pressure.

CORROSION AND WEATHER RESISTANCE

It is resistant to deep sea water corrosion and has good weather resistance. Excellent machinning performance

Rotational Molding Offshore Buoys

Roto-moulded linear polythylene filed with high density polyurethane foam

Rotational moulded marine buoys include mooring uobys, marker buoys, navigation buoys, and ocean buoys. Marine foam buoys are made of UN-stabilised polyethylene, designed for marine navigation and mooring system.

Marine foam buoys are manufactured by advanced rotationally-moulded technology. Marine buoys are protedted with strong, high-visibility durable UV resistance virgin polyethylene, inner filled closed-cell foam. Offshore foam buoys is unsinkable design even of damage of outer skin.

Steel Offshore Buoys

Steel buoys have mooring buoys and pipeline buoys. The steel buoys are made of high-quality steel that is used for the naval field, with a thickness greater than 10mm. Float diameters available from 2 to 3 meters are submitted to an anti-oxidation treatment providing maintenance periods above 5 years. They are characterized by their high shock resistance and stability.

Need more information ?

Welcome you contact us to get more information. We will provide more information about our solid buoyancy material used for the offshore mooring, surface and subsea.

Let's win together!

Telephone: +86-532-67730629

Mobile: +86-186 6025 7896 (WhatsApp)

Email: sales@doowinmarine.com