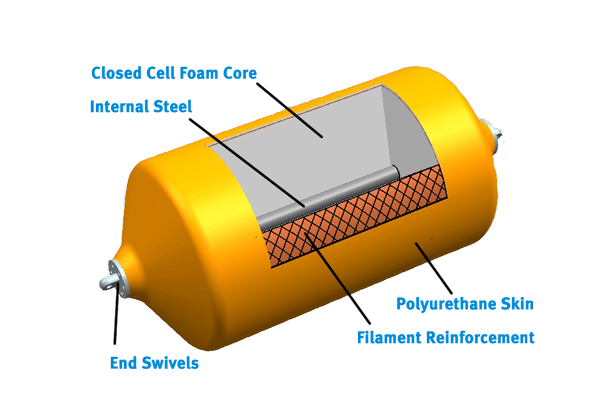

Doowin Marine foam fenders, donut fenders, and offshore foam buoys all share the same construction technology centred on a closed-cell polyethylene foam core and an outer skin of reinforced polyurethane elastomer. The foam absorbs the impacts whilst the skin resists wear and tear in an aggressive environment.

High Energy

Core foam comes in many different types. Different density foam can absorb different impact energy and generate lower reaction forces.

Unsinkable

The closed cell foam structure makes punctures a thing of the past. Every cell is separate and so water cannot migrate into the foam.

Strong Reinforcement

Skin and reinforcement are applied simultaneously. Nylon mesh are applied at during PU coating

Wear Resistant

The polyurethane elastomer is spray applied. This creates a high quality and homogeneous skin matrix combining extreme wear resistance.

Floating Foam Filled Fenders

Foam fenders is one kind tough heavy-duty and unsinkable floating fenders system. They are often used for harbor, offshore and ship-to-ship application. Foam filled fenders have higher energy absorption with lower reaction force. Its performance is higher than the pneumatic rubber fenders and other marine fenders. Its self-floating characteristic ensure foam fenders are workable for ship-to-ship operation.

Netless foam filled fenders

Netted foam fenders

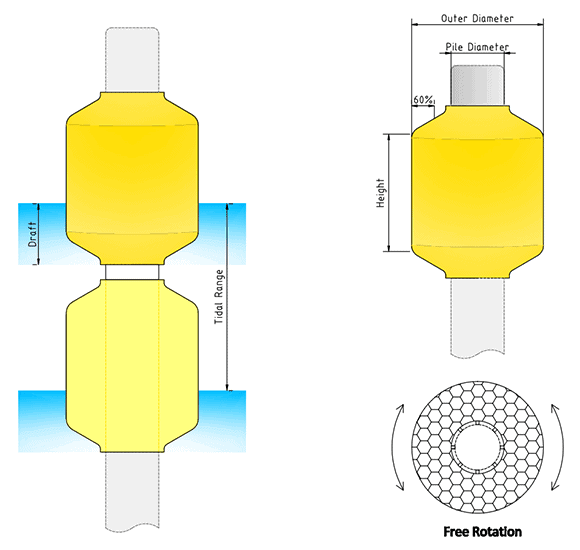

Donut Foam Fenders

The donut fender is an effective fendering solution for the berthing dolphins, guiding structures, and corner protections. Donut fender is seprated with the tubular pipe. There is low friction bearings pad, which can ensure the donut fender float up and down and freely rotates.

Small Standard Duty Shipboard Foam Fenders

The ocean guard small standard duty (SSD) shipboard foam fenders are designed for quick and convenient handling. These SSD foam fenders are constructed with a closed-cell foam core and ultra-tough polyurethane elastomeric skin. It is easy to install because of is lightweight. One or two workers can handle it. SSD foam fender is ideal for the limited storage space on board of naval and commercial vessels because of its small size.

SSD Foam Fenders Type:

- Portable Type Foam Fenders

- Ped Eye End Foam Fenders

- Hawser Pipe Type Foam Fenders

Floating Foam Filled Fenders

Welcome you contact us to get more information. We will provide more information about foam filled fenders, donut fenders, shipboard foam fenders, and vessel fenders.

Let's win together!

Telephone: +86-532-67730629

Mobile: +86-186 6025 7896 (WhatsApp)

Email: sales@doowinmarine.com