Subsea Buoyancy Module

Made of Syntactic Foam or Chemical Foam

SUBSEA BUOYANCY SOLUTION

The subsea buoyancy material is mainly used underwater. Based on its characteristics of low density and high pressure resistance, it mainly provides the required buoyancy for underwater operation equipment. Spray coating or protective layer treatment can be applied to the surface as required. Often manufactured and processed into floats, buoys and other counterweight products. It can also be directly machined into product parts.

It can not only meet the mechanical requirements of the product structure, but also greatly reduce the product weight and other functions. The application of this material realizes the functions that are difficult for metal structural parts to realize. At present, it has been used in underwater deep submersibles, underwater robots, etc., and can be used safely at depths of several thousand meters underwater.

Subsea Buoyancy Products Made of Syntactic Foam

Most of our products are custom made, so there is no standard specification sheet.

Subsea Buoyancy Blocks

ROV Buoyancy Modules

AUV/RUV Floats

Submersible Marker System

Cable Floats

Optical Cable Floats

ROV Cable Floats

Submarine Cable Float

Spherical Subsurface Mooring Buoys

Subsea Buoys

Submarine Trenching Floats

Customized Buoyancy Modules

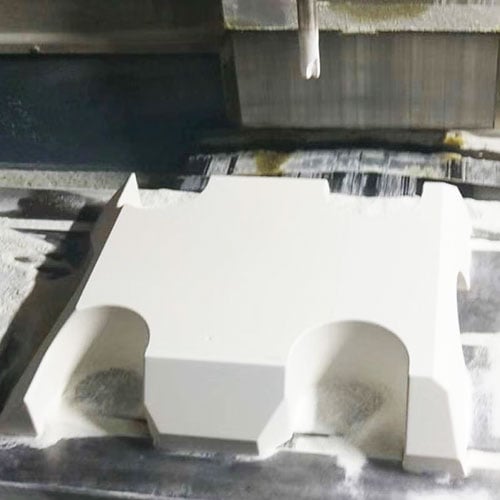

Spotlight on Production Proces: What You Need to Know

The fittings at both ends can be customized according to customer needs, including galvanized or stainless steel

We have two kinds standard syntactic foam block 320x320x100mm and 500x500x100mm.

We glue the standard buoyancy blocks at a constant temperature using a special glue.

The buoyancy blocks are cut by high-precision CNC machines according to the customer’s drawings.

External high-strength and wear-resistantt polyurea coating protection enaables better performannce.

Our Product Display: Field-proven Buoyancy Solutions

Subsea Buoyancy Syntactic Foam

Subsea solid buoyancy material (syntactic foam) is a lightweight composite formed by embedding hollow microspheres in polymer matrices. These low-density (0.35-0.7g/cm³), high-strength (1-100MPa) materials feature minimal water absorption (<2%) and corrosion resistance, serving as essential counterweights for underwater equipment. Their applications enable deeper dives, increased payload capacity, and stable operation in deep-sea environments, making them crucial for 21st-century subsea technology.

Contact our marine specialists to discuss your buoyancy solution

Let's win together!

Telephone: +86-532-67730629

Mobile: +86-186 6025 7896 (WhatsApp)

Email: sales@doowinmarine.com