Mooring Buoys

- Home

- Products

- Offshore Buoys

- Mooring Buoys

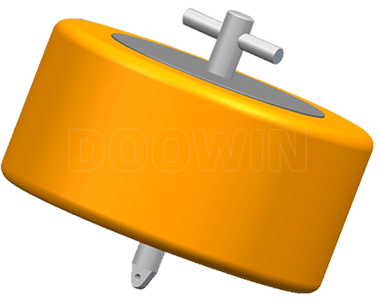

Foam mooring buoys are in service for inland waterways and offshore instead of traditional steel mooring buoys.

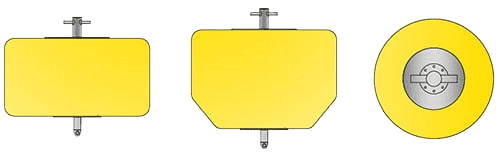

The cylindrical mooring buoy is one kind of representative mooring buoy. The cylindrical mooring buoys can be supplied in chain-through type, or equipped with pad-eye, crucifix, quick release hook, and maker or navigation equipment. Other varieties of end fittings are available to suit every case application. All end fittings are made of galvanized or painted steel to resist seawater corrosion. Application for commercial mooring buoys are offshore and remote mooring, temporary mooring of vessels in a port, dock or harbour, additional mooring for large vessels on berthing/mooring dolphins and longer term mooring for infrequently used vessels.

Spotlight on Production Proces: What You Need to Know

The fittings at both ends can be customized according to customer needs, including galvanized or stainless steel

Make the inner steel structure and carry out tensile strength test.

Process the internal foam core material.

Spray polyurethane elastomer, reinforced with nylon

Inspection before leaving the factory, or inspection by a third party

Mooring Buoys Features

Our Mooring Buoys

-

PU Protective Outer Skin

Reinforced urethane elastomer skin with 3~20mm thickness

-

Self-fendering

High impact absorption capacity

-

Inner PE/EVA Foam

Unskinable closed cell rigid foam core

-

Upper End Fitting

Various end fitting options available

-

Internal Steel Core

For better support and balance

-

Reinforcement Layer

Reinforced nylon filament ensures polyurethane elastomer protective coating has higher tear strength

JMB Mooring Buoys Specification

DOOWIN MARINE supplies a range of mooring buoys with reserve buoyancy between 75kg and 1000kg. They are a heavy-duty offshore mooring buoy with a structural tie-bar offering the user a product with unprecedented strength and reliability due to its fully sealed design.

The mooring foam buoys and tie-bars are manufactured in China allowing a quick turnaround time and high level of quality control. DOOWIN MARINE mooring buoys are foam-filled with marine-grade 100% closed-cell foam to ensure they remain buoyant even if the hull is damaged. The polyurethane spraying technology ensures that the buoys have a much higher strength and durability than the traditional rota-moulding process.

Customized sizes are avaialbe upon request.

Type | Buoyancy | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | I (mm) | J (mm) | Shackle Size |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

JMB-75 | 75kg | 580 | 518 | 208 | 310 | 260 | 670 | 250 | 50 | 10 | 20 | 3.25T |

JMB-75H | 75kg | 580 | 518 | 208 | 310 | 260 | 775 | 250 | 130 | 30 | 45 | 13.5T |

JMB-150 | 150kg | 740 | 660 | 265 | 395 | 390 | 850 | 280 | 100 | 20 | 32 | 9.5T |

JMB-250 | 250kg | 860 | 770 | 265 | 505 | 430 | 980 | 320 | 100 | 20 | 34 | 9.5T |

JMB-500 | 500kg | 1080 | 940 | 350 | 590 | 520 | 1285 | 400 | 150 | 25 | 39 | 13.5T |

JMB-1000 | 1000kg | 1400 | 1250 | 500 | 750 | 640 | 1670 | 500 | 155 | 40 | 58 | 35T |

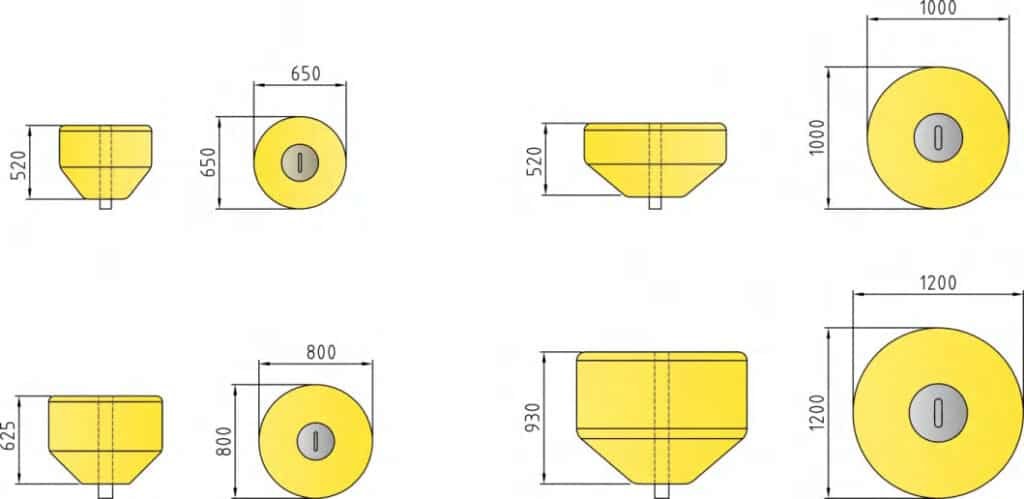

Cylindrical Mooring Buoys Specification

The below table shows the most commonly requested size only. The standard color is yellow and orange.

Type | Height (mm) | Diameter (mm) | Overall Height (mm) | Weight (kg) | Net Buoyancy (kg) | Net Buoyancy (lbs) |

|---|---|---|---|---|---|---|

CMB1 | 700 | 1500 | 1500 | 161 | 1000 | 2207 |

CMB3 | 1100 | 2000 | 2200 | 544 | 3000 | 6620 |

CMB5 | 1500 | 2500 | 2500 | 1104 | 5000 | 11033 |

CMB8 | 1500 | 2500 | 3100 | 1698 | 8000 | 17652 |

CMB10 | 1500 | 2500 | 3300 | 1924 | 10000 | 22065 |

CMB15 | 2000 | 3000 | 3500 | 2886 | 15000 | 33098 |

CMB20 | 2000 | 3000 | 4000 | 4021 | 20000 | 44131 |

CMB25 | 2000 | 3000 | 4000 | 5027 | 25000 | 55163 |

CMB30 | 3000 | 4000 | 4200 | 6650 | 30000 | 66196 |

SM Mooring Buoys

The mooring buoys can be installed with various fittings on the top. And the mooring buoys can be designed to meet different requests. It has the same design as common mooring buoys.

The large mooring tube with 82.5mm ID will accept mooring chain of up to 20mm in diameter. The mooring tube is not molded into the buoy but slides into a tubular section that runs down the center of the buoy enabling the tube to be replaced at any stage during the product’s service life.

Customized size are available upon request.

Foam-Filled Buoyancy System

Welcome you contact us to get more information. We will provide more information about foam filled oil & gas buoyancies.

Let's win together!

Telephone: +86-532-67730629

Mobile: +86-186 6025 7896 (WhatsApp)

Email: sales@doowinmarine.com