The airbag market is currently chaotic. The price of airbags varies greatly. This brings the difficulty of identification and selection to many buyers. Below we explain the difference in airbag cost from the aspect of raw materials. They are some secrets that manufacturers don’t want you to know.

1. Reinforcing Material

1.1 ISO 17357 Rules About Reinforcing Material

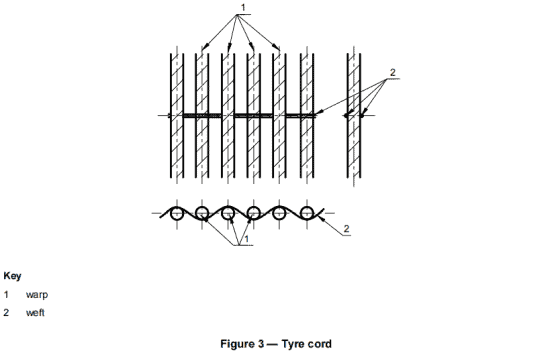

An airbag is to be constructed of an outer rubber layer, one or more synthetic-tire-cord layers, and an inner rubber layer. The arrangement of synthetic-tire-cord reinforcement layers is shown in Figure 3. All materials shall be vulcanized firmly.

As a reinforcing material, the warp should be (90 ± 5) cords per 100 mm in width, and the breaking strength shall be more than 205 N per cord.

1.2 The Secret of Reinforcing Material Rubber Material

Synthetic tire cords normally refer to nylon cords, which are the most expensive material in ship launching airbags. Reinforcing material, tire cord is the key factor that influences airbag performance.

Please refer to the below table, which shows the comparison of different nylon 66 cords’ performance.

From the above table, we can know both standard nylon 66 (1400dtex/2) cords and (1400dtex/3) cords meet ISO 14409 requirement (breaking strength shall be more than 205 N per cord). They are also the two most commonly used reinforcing materials in the market. The manufacturer often calls it “three-strand cords” and “two-strand cords”.

Some suppliers tell the buyers that they use 1400dtex/3 (three-strand cords). But use the 1400dtex/2 (two-strand cords) instead of when producing airbag. Or, they mix three-strand cords and two-strand cords. It is hard to know it for the buyers.

There are even some manufacturers using dacron cords (polyester fiber) instead of nylon cords. Dacron cords performance is nowhere near that of nylon cords. The cost difference is more than 50%!!

2. Rubber Material

2. 1 ISO 17357 Rules About Rubber Material

An airbag is to be constructed of an outer rubber layer, one or more synthetic-tire-cord layers, and an inner rubber layer.

Prior to the airbag production, the outer and inner rubber layers shall be tested to meet the Table 2 criteria in accordance with the test methods given in the International Standards listed in Table 2. While only one satisfactory sample per batch is required for test numbers 1 through 3, all others must be tested for test numbers 4 through 9 annually. If the first sample fails, two additional samples shall be tested. If the additional samples pass the test requirements, the materials will be deemed to have passed the test. Otherwise, the materials will be deemed to have failed the test and another batch of materials shall be selected.

2.2 The secret of Rubber Material

Qualified rubber is the foundation of the launching airbags. The rubber formula and rubber contents decide airbag cost and the performance, lifespan. In order to meet ISO 14409 requirements, it is necessary to condition to use the new rubber. The qualified rubber can ensure the top-loading capacity when it has to bear very high heavy ships.

Some suppliers use recycled or reclaimed rubber material in airbag production. The manufacturer can save costs in this way. But recycled and reclaimed rubber has substantially lower elasticity and has a very fast aging rate which compromises the integrity of airbags. You would find these airbags appear problems and burst very easily after using these recycled rubber airbags a couple of times.

Welcome you contact us to talk more secrets that you you want to know.