Customized Marine Launching Airbags

DOOWIN MARINE Launches Comprehensive Customization Service for Ship Launching Rubber Airbags, Meeting Diverse Global Shipyard Needs DOOWIN MARINE, a leading manufacturer and pioneer in maritime

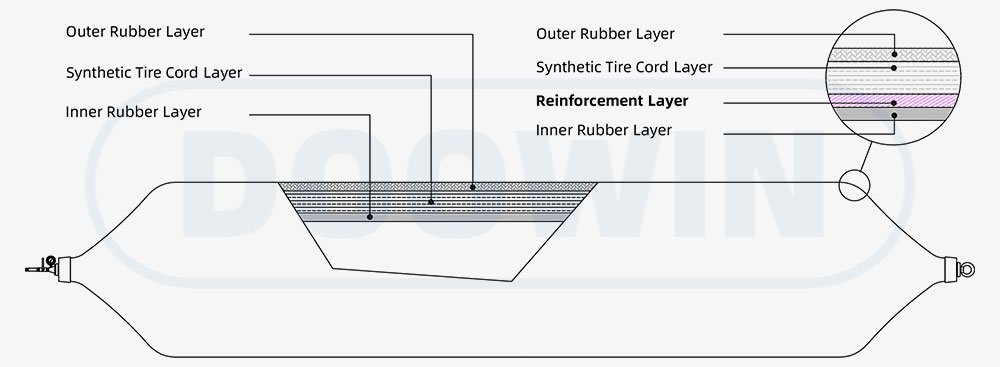

Ship launching airbags are known as roller bags, launching air balloons, inflatable marine airbags, air lift bags, and salvage bags. Ship launching airbags are specialized marine rubber air bags that are used for launching marine vessels. ship landing or haul-outs. Marine rubber airbags are also widely used in loading, floating, lifting and moving sunken ships, and salvaging stranded boats. Rubber airbags are made of heavy-duty synthetic-tire-cord layers with inner and out rubber layers in a long cylindrical balloon shape.

Ship launching or upgrading using marine airbags is an innovative ship-launching technology. It overcomes the disadvantage of “end-on launching”, “side ship launching”, and “float-out”. This ship-launching technology overcomes the restrictions of the fixed launching track of side-launch.

This flexible ship launching technology is accepted by more shipyards worldwide because of its advantages of saving time, investment, flexibility, and safety. We are constantly innovating in terms of design, material usage, & manufacturing technologies throughout the years to ensure flexibility, safety, and reliability.

Up to now, more cargo vessels, barges, chemical tankers, tugboats, AHTS vessels, floating docks, and even construction caissons have all been launched using our ship-launching rubber airbags. The biggest vessel launched by ship launching airbags up to 100,000DWT.

All Doowin Marine ship launching airbags are manufactured and tested fully compliant with ISO 14409:2011 Ships and marine technology — Ship launching airbags. To learn more technology, please kindly refer ISO 17682:2013 Ships and marine technology — Methodology for ship launching utilizing air bags

We are proud to provide the highest quality ship launching airbags, together with expert service and timely customer support for clients from Southeast Asia, Europe, Turkey, Middle-East, North America, Africa, South America.. Let’s help you successfully complete your project – on budget and on time.

Rubber airbags are constructed of an out rubber layer, multi-layer synthetic-tire-cord layers, and inner rubber layer vulcanized firmly. More layers are applied at the end shoulders.

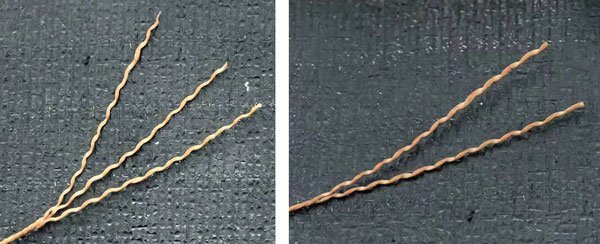

Synthetic-tire-cord layer is reinforcement layer of the ship launching airbags which are made of rubber coated synthetic-tire-cord fabrics. Many synthetic-tire cord layers are twined at ideal angles by unique and patented "Holistic Wrapping Technology". To hold the internal pressure and to distribute the stress evenly. We use the 1400 dtex/2 or 1400 dtex/3 type synthetic-tire-cord fabric. The warp is over 95 cords per 100 mm in width. The breaking strength is more than 310 N per cords.

Prior to the air bag production, the outer and inner rubber layers shall be tested to meet the criteria in accordance with the test methods given in the International Standards listed below. The outer rubber layer covers the outside of ship launching airbags. To protects the cord layers from abrasion and other external forces. This compound has sufficient tensile and tear strength to withstand any weather condition and hard usage.

No. | Test Item | Value | Standard |

|---|---|---|---|

1 | Tensile Strength, Mpa | ≥18 | ISO 37 |

2 | Elongation at break, % | ≥400 | ISO 37 |

3 | Hardness, ° (Shore A) | 60±10 | ISO 7619-1 |

4 | Tear Strength, N/cm | ≥400 | ISO 34-1 |

5 | Compression set, % (70℃±1℃,22h) | ≤30 | ISO 815-1 |

6* | Holding of pull lengthening, % | ≥80 | ISO 188 |

7* | Holding of elongation at break, % | ≥80 | ISO 188 |

8* | Change of hardness, ° (Shore A) | ≤8 | ISO 7619-1 |

9 | Static ozone aging at 40℃ x 96h, extension 20% | No crack | ISO 1431-1 |

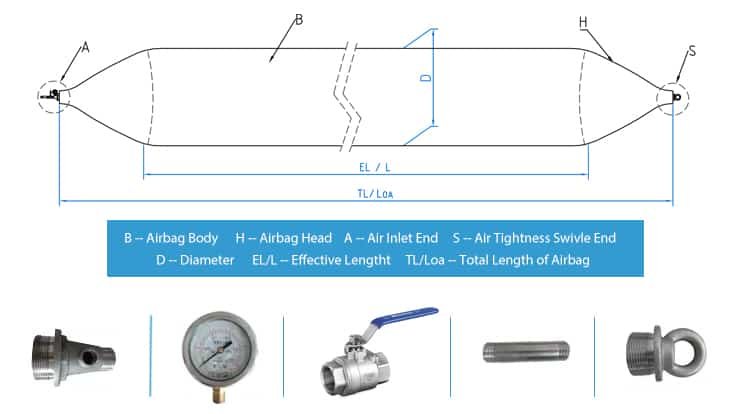

Rubber airbags are cylindrical balloon body, with two conical head and end mouth. Swivels and air inlet kits are screwed with end mouth.

You can choose the required diameter and effective length to meet your projects. Refer to how to select marine rubber airbags to know more. The below specification only is our standard specification arrange. Other specifications Ship Launching Airbags also can be supplied upon clients’ request. For other information, you also can refer Airbag Launching.

Air Bag Parameter | Ship Launching Airbags Size |

|---|---|

Product Name | Ship Launching Marine Rubber Airbags |

Diameter (D) | 0.5 ~ 3m, or customized diameter |

Effective Length (EL) | 1 ~ 32m, or customized length |

Total Length (TL) | 1.2 ~ 35m, or customized length |

Loading Capacity | 10 ~ 40 ton/m, or customized capacity |

Model of Airbags | QP-ordinary, QG-high-bearing, QS-superhigh bearing |

1. The end of airbag body 2. End flange (Q235 H.D.G)

3. Sealing Washer 4. Three-direction connector at the inflate end (Q235 H.D.G)

5. 3/4′ Ball Valves at the inflate end (Brass) 6. Hose connection at the inflate end (Q235)

7. High-quality Pressure Gauge 8. End plug at the tightness end (Q235 H.D.G)

Ship Launching airbags are categorized by the following three types according to the bearing capacity, per meter in length. We define the number of layers, which means the number of Synthetic-tyre-cord layers, to confirm the Safety Working Pressure. Other types is available upon clients’ request.

For example: QG6/1.5x15

QG6: 6 layers of cord fabric + 1 rubber layer

1.5: Diameter is 1.5m

15: Effective length is 15m

The bearing capacity of ship-launching airbags was calculated based on the working pressure, and contact area. Herein, working pressure was got upon the burst pressure and safety working factor.

Because of the flexibility of the rubber airbag, the contact area will be affected by some terms. It includes carried ship condition, and the different positions from the gravity center during the process of ship launching and landing. So the bearing capacity of rubber airbags will vary as well as the contact area.

The approximate bearing capacity can be calculated as follows:

F=PS S=π x (D-H)/2

Where:

F is the bearing capacity

P is the working pressure

S is the contact area

P is the percentage of deformation (%);

D is the original diameter of the airbag (m);

H is the height of the compressed air bag (m)

Type No. | Diameter (m) | Initial Internal Pressure for Test (kPa) | Rated Working Pressure (kPa) | Bearing Capacity at 70% compress deformation (KN/m) | Minimum Burst Pressure (kPa) |

|---|---|---|---|---|---|

QP5 | 0.8 | 48 | 210 | 184 | 630 |

1.0 | 35 | 170 | 186 | 510 | |

1.2 | 28 | 140 | 185 | 420 | |

1.5 | 20 | 110 | 181 | 330 | |

1.8 | 16 | 90 | 178 | 270 | |

2.0 | 14 | 80 | 176 | 240 | |

QG6 | 0.8 | 56 | 245 | 215 | 740 |

1.0 | 45 | 200 | 219 | 600 | |

1.2 | 32 | 165 | 217 | 490 | |

1.5 | 25 | 130 | 218 | 390 | |

1.8 | 20 | 110 | 220 | 330 | |

2.0 | 18 | 100 | 220 | 300 | |

QG7 | 0.8 | 64 | 270 | 237 | 810 |

1.0 | 50 | 220 | 242 | 660 | |

1.2 | 38 | 190 | 251 | 570 | |

1.5 | 29 | 150 | 247 | 450 | |

1.8 | 25 | 130 | 257 | 390 | |

2.0 | 23 | 120 | 264 | 360 | |

QG8 | 0.8 | 70 | 300 | 264 | 900 |

1.0 | 54 | 240 | 264 | 720 | |

1.2 | 45 | 210 | 277 | 630 | |

1.5 | 32 | 170 | 280 | 510 | |

1.8 | 29 | 150 | 297 | 450 | |

2.0 | 26 | 140 | 308 | 420 |

Superior Manufacturing & Quality Control Processes from the selection of raw materials to the highly skilled production process

Air bags create high lifting capacity with safer low pressure. One air bag can lift 300~500 ton.

Heavy-duty synthetic-tire-cord layers are the framework material. It can bear high working pressure.

Rubber airbags have 6~12 plies reinforcement layers to withstand most abrasion and puncture.

The design lifespan of ship launching rubber airbags is over 6 years with the correct storage.

Ship Launching Airbags. Also known as inflatable marine airbags, roller bags, air lift bags, and salvage bags. Airbags range in size from 0.8 to 2.5m diameter, with lengths of 5.0m to 25.0m ‘effective length’. Airbags are used for ship launching, haul-outs, loading, and floating.

The weight of ship launching airbags is calculated by airbag surface area. When you care too much about weight, you may be misled by some manufacturers. Please remember “It’s not that the heavier the airbag, the better the quality. Weight is not a good indicator of quality.”

All Doowin Marine ship launching airbags are manufactured and tested fully compliant with ISO 14409 “Ships and marine technology – ship launching airbags“, certificated by BV, CCS, LR, ABS. There are two Chinese standards and two ISO standards for ship launching airbags production and using.

It is very easy to distinguish used and new airbags. If there are abrasions on the airbags body, then it is used one. For the new airbags, it’s surface maybe looks ugly and dirty. It is because we use French chalk in the vulcanization process. When the water vapor in the vulcanization tank is mixed with French chalk, the surface will appear very dirty.

Our unique overall winding technology is different from the current mainstream airbag production technology. We innovate and improve on the basis of mainstream production technology. The airbag produced by the optimal winding angle technology can exert the maximum effect of the material, save the cost, and have a stronger lifting force.

We will provide the Manufacturer Certificate and Certificate of Compliance. Meanwhile, we also can provide BV, CCS, LR, ABS third party certificate upon buyer’s request.

Generally speaking, the number of layers refers to the number of layers of the skeleton material, that is the number of layers of the synthetic-tyre-cord fabric layer. The number of layers mentioned by some small manufacturers refers to the number of layers of cord fabric plus the number of layers of rubber. This is very incorrect. They cheat consumers by confusing concepts.

Marine rubber airbags are not single-use products. It can be used for many times. But cannot define the exact number. General speaking marine airbags have 5~8 years lifespan under the correct usage and proper maintenance.

General speaking marine airbags have 5~8 years lifespan under the correct usage and proper maintenance. But it also depends on how frequently airbags were used and how they are maintained and stored. After using 3~5 years, the rubber airbags must be fully inspected to determine if the airbag can continue to be used.

The ship launching airbags price is calculated by the airbag’s surface area, not weight. Rubber airbag has two cone shape ends. But we normally, make the airbags as cylindrical shape to calculate its surface area. Its calculate formal is S=π x Diameter x (Diameter+Effective Length) x layer numbers. Then, multiply the surface area by the unit price. The unit surface price is quite different for different factories, please contact us to get the unit price per square meter.

The storage influences the airbag’s lifespan. So, it is very important. Ship launching airbags should be cleaned with fresh water and dried then powdered with French chalk powder. Ship launching airbags should be stored in cool, dry sheltered place, kept away from chemicals, gasoline, solvent etc. Ship launching airbags can be piled for storing.

Ship launching or upgrading using marine airbags is an innovative technology that has the utmost bright prospect in shipbuilding. It overcomes the disadvantage of fixed track launching by which the productivity of shipbuilding and ship repairing were limited in the small-sized and medium-sized shipyards.

Excellent in Practise

Based on the ship shapes, the ship may be launched, using air bags, by either end launching type or side launching type.

DOOWIN MARINE Launches Comprehensive Customization Service for Ship Launching Rubber Airbags, Meeting Diverse Global Shipyard Needs DOOWIN MARINE, a leading manufacturer and pioneer in maritime

Leading Maritime Supplier Ships Revolutionary Rubber Airbags to Global Market [Qingdao, China, September 19, 2025] – DOOWIN MARINE, a pioneer in maritime innovation, has successfully dispatched

Marine Salvage Rubber Airbags: Engineering Excellence in Underwater Recovery Marine salvage rubber airbags have become indispensable tools in modern underwater recovery and marine engineering. Crafted

We work for many shipyards, ports, and offshore companies all over the world.

Welcome you visit Why Doowin Marine to know more information.

Welcome you contact us to get more information. We will provide more information about ship launching airbag selection, use and storage, launching or landing technology, etc. Free ISO 14409:2011 and ISO 17682:2013. Investigation on Safety Assessment of Ship Launching with Airbags

Telephone: +86-532-67730629

Mobile: +86-186 6025 7896 (WhatsApp)

Email: sales@doowinmarine.com

It’s easy: all we need is your eternal love. But we’ll settle for your email.

Email: sales@doowinmarine.com

Mobile: +86-186 6025 7896 (WhatsaApp)

Telephone: +86-532-87788178

We will contact you within 1 working day.